Sleeking-Lamination

1. Introducing Sleeking-Lamination

First Choice Books is proud to add sleeking-lamination to the finishing options we now offer our clients. We are very excited about our newly acquired sleeking laminator which efficiently provides this innovative service. If you’re not sure what sleeking-lamination is or how it works, read on and we’ll happily answer all of your publishing related questions below!

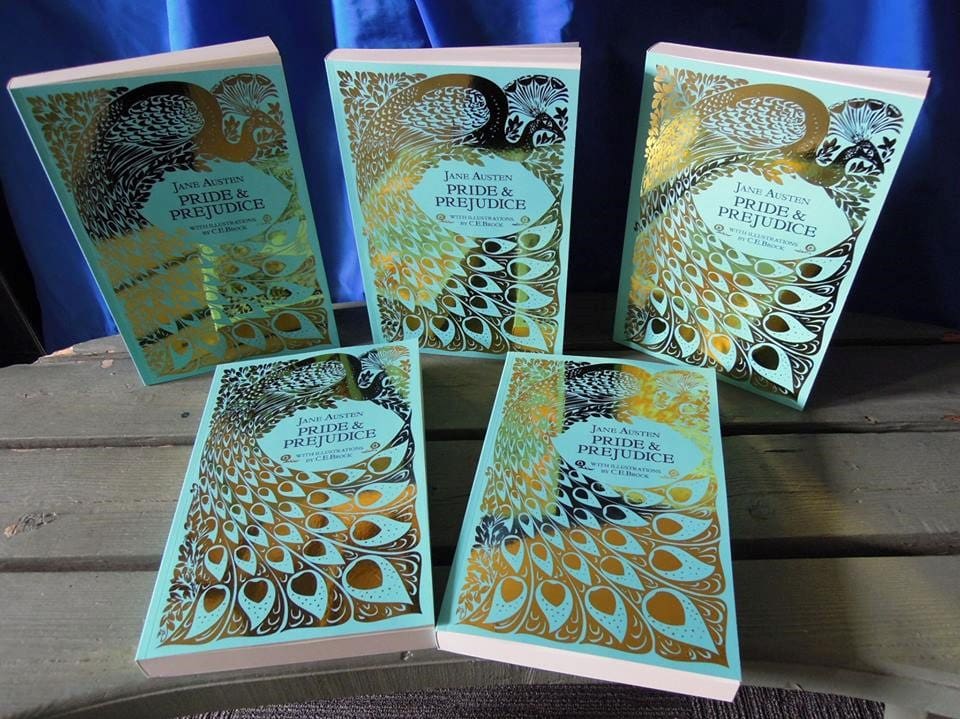

Sleeking is a registered trademark of GMP Co. Ltd., distributors of the digital lamination machine we now use. We are able to apply a clear gloss or matte film to your entire printed book cover, greeting or business card. In addition the sleeking laminator allows the application of gloss, matte, holographic and metallic (foil) overlays, almost identical to spot varnish, to a portion of an image on the cover and background image too. We can now over-print unique designs onto your products. The addition of a sleeked finish, similar to spot varnish, can bring a definite ‘wow’ factor to your printing. Yes books are judged by their covers!

2. How Sleeking Works

There are three stages to the sleeking process: artwork, printing and laminating. In the artwork stage a separate colour layer is created for the spot area or background area that is to have the special effect added (or multiple layers for more than one effect). This layer is then printed on the digital press in a black colour which the laminating or metallic film adheres to when run through the sleeking lamination machine. After the first run, all sleeked pages are then run through the digital printer again to add the colour layers.

As a customer, you get to select several variants of sleeking-lamination: gloss, matte, holographic, or metallic finishes. Interestingly, as seen in the example above of our latest sleeking project, the results can be stunning. The sleeked, reflective look adds a significant amount of value to the finished product, and can also often justify higher prices for a self-published books.

3. Benefits of Sleeking-Lamination

There are several benefits of this new sleeking-lamination process.

a. Spot varnish effects can be reproduced at a fraction of the cost, by using the patented sleeking process.

b. The costs of making blocks and dyes is eliminated with sleeking-lamination, making it less labour intensive. Now either short or long-run jobs can be completed with ease. The sleeking machine can be run single-handedly. All of this equates to shorter lead times for specialty jobs, which can now be turned around quickly by our staff.

c. Your creativity is matched to our print quality when we use sleeking-lamination. We are extremely happy to be able to invite you along on this exciting sleeking-lamination journey with us. The only limit is your imagination!

“The true sign of intelligence is not knowledge but imagination.” – Albert Einstein